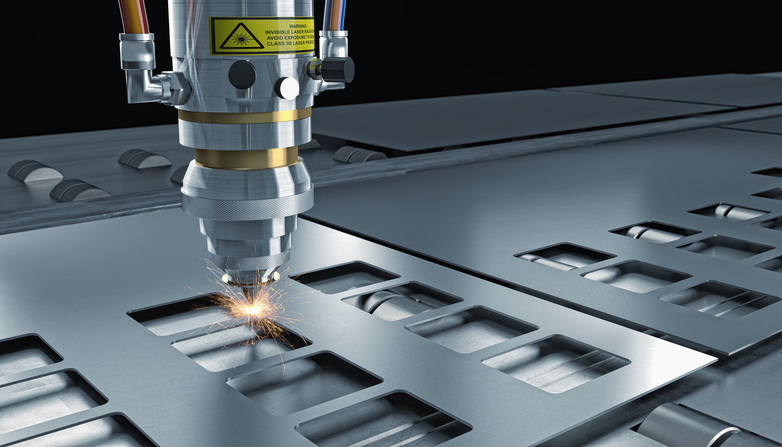

Laser cutting is well-known for its ability to properly cut metal at high speeds. When working with thicker materials, the cutting time increases, but they continue to work swiftly. Laser cutters are ideally suited for both small and large-scale operations, and they may assist save manufacturing costs by reducing the time it takes to minimise waste. Manufacturers may provide the quickest cutting speeds on the market if they employ the proper sort of laser cutter. Laser cutters may also be quite effective in assisting with the quick creation of designs. Laser cutters boost manufacturing efficiency in addition to shortening cutting timeframes.

Sophistication

When it concerns to accuracy, laser cutters are practically unparalleled. CNC routers instruct cutters to conduct complicated cuts into intricate geometric designs, while lasers generate these cuts and forms with great precision. A laser cutter produces crisp edges and a flawless finish. Anything that comes into contact with the laser is burnt, evaporated, or melted. As a result, there will be no superfluous debris, resulting in a rough cut. This precision not only results in high-quality products, but it also helps to eliminate waste during manufacturing. Sophistication Because machines can manufacture parts with such high accuracy, they are an excellent choice for cutting parts for aircraft and healthcare products production, where stringent dimensional tolerances and quality requirements are required.

Power Consumption

A laser cutter’s efficiency, paired with its modern technology, allows it to require less energy than conventional cutting processes. In reality, laser cutters generally consume roughly 10kW of electricity during a cutting session, whereas other cutting mechanisms consume over 50kW. Laser cutters may help producers improve operational efficiency and use less energy, both as a cost-cutting technique and as an ecologically beneficial one. Laser cutters are an excellent technique to reduce energy consumption throughout the manufacturing process.

Standardisation

Even though cutters make such exact cuts, you can be confident that your components and assemblies are laser perfect. Because laser cutting is so accurate, you may be confident that the cuts will be exactly as programmed. As a result of this accuracy and programming, each manufacturing job is consistent. When making several copies of the same material, you can be certain that each duplicate is identical. You may also be confident that the laser cutter will deliver the same high-quality product every time you use it.

Elegance

Number of co laser beams provide a wide range of applications that laser cutters may assist with. They can cut substances of different thicknesses and sorts. They can effortlessly cut both basic and complicated constructions. Machines can also cut a broad range of materials with precision, including metals, alloys, diamonds, polymers, woods, and glass. Laser cutters can cut detailed and very exact forms out of all of these components, even various materials at the same time. Because of its sensitivity and efficiency, laser cutters are able to generate practically limitless varieties of cuts.

Having completed Qualifications Have Been Reduced

Because laser cutters create extremely accurate cuts, they will result in less finishing procedures. Laser cutters provide edges that are smooth and devoid of burrs. The beams are also well concentrated, which means there will be no interior faults caused by heat transmission. Quality inspections will take less time since laser cutters generate high-quality, accurate cuts. They guarantee that all component standards are satisfied, resulting in efficient quality inspections.

Nonetheless, there are several widespread myths regarding laser cutting that linger. One common myth regarding laser cutting is that the laser head comes into direct contact with the substance, when it does not. It uses high-energy beam approach to ensure tighter cutting standards and more accuracy. Another prevalent myth about laser cutting is that its efficiency is proportional to raw laser power. True, fibre laser technology has boosted laser beam strength over time; nevertheless, enhanced cutting performance is determined by beam speed, not raw laser power.